Call us on 01792 893985 if you’d like us to send you a sample.

Send Us an Enquiry

Please include the length of your sheets, how many sheets you’d like (the sheets give 1m coverage) and your postcode if you would like a price inclusive of delivery.

Nationwide Delivery

bespoke manufacturing

Over 50 years experience

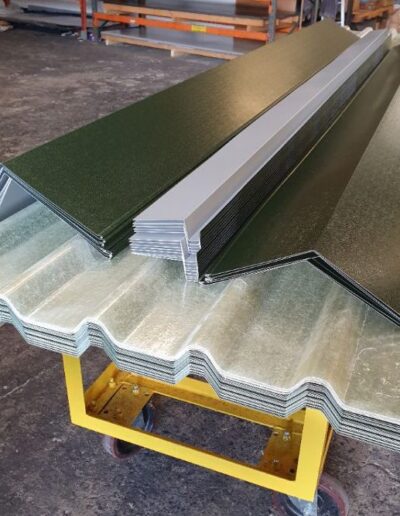

Roofing Sheets

Roofing sheets are an effective, modern solution for any roofing requirements. They can be used as a standalone roofing material or as cladding for an existing structure. Our expertise and dedication to providing you with a great product is apparent with our roofing sheets from your first contact with us.

If you are looking to replace the roof on a barn or a durable material for a new building, our roofing sheets have got you covered. And, with numerous styles to choose from, an aesthetically pleasing result can easily be achieved. The roof sheets are suitable for domestic or commercial environments and can stand the test of time.

Benefits of roofing sheets

The benefit of using roofing sheets rather than a traditional roofing solution is that it saves substantially on the costs. Metal sheets can be applied in large sections that can be designed and measured to meet your requirements, rather than applying many individual tiles. Furthermore, their strength and reliability compared to tiling is significantly better, providing you with the peace of mind that your structure is protected from the outdoor elements. As well as this, should a section be damaged, it is quick and simple to install a replacement panel – this is much more efficient than replacing broken tiles.

Our roofing sheets can be designed to mimic the look of a tiled roof, without any of the drawbacks. Tile effect sheets can give you the traditional look without breaking the bank. They can be painted and coated to protect the steel from years of rain and wind. A quality roof sheet installation can last well over 10 years; therefore, they are a great choice for any long-term developments. We also provide: box profile, anti-condensation and insulated roofing sheets. Hence, there is a product that will suit your needs.

What are the best roofing sheets for a barn, outbuildings, industrial buildings?

The best metal sheets for any building is dependent on what you want to use it for right now … whether you have any future plans for the building and what your budget is.

A single skin Polyester, painted or powder coated roof sheet will be a good starting point, giving you a watertight building quickly and cost effectively.

If you want metal roof sheets which will give you a longer life for not a great deal more money, a Plastisol PVC coated sheet will fit the bill.

Single skin sheets can sometimes give rise to condensation forming on the underside of the sheets. This condensation of the sheets can drop from the underside of the metal roof cladding and affect the items being stored in the barn. A cost effective solution for dealing with the problem is Dr!pStop! which is applied to the underside of the metal roofing sheets during manufacture. This holds the condensation in suspension within a special non-woven fabric until it evaporates away and is vented.

The Dr!pStop! also acts as an acoustic layer, deadening sound and providing a amount of insulation.

Metal roofing sheets with Dr!pStop! are also called anti-con or anti condensation roofing sheets … but this is technically incorrect. The condensation still continues to form. It is held within the non-woven fabric.

If you are likely to be putting any heat into the building or if you want to significantly reduce the chances of frost within the building, you may want to consider insulated roof sheets.

These are available with varying levels of certification with insulation thicknesses ranging from 40mm up to 135mm.

Corrugated roofing sheets

Corrugated roof sheets normally refers to the roofing sheets which look like a curved wave shape … or a sine wave if you remember your science lessons from school.

They are normally fixed using ‘J’ bolts which hook under the supporting subframe and through the crown of the curve. This tends to require pre-drilling of the sheets and a second pair of hands to make sure everything is in place prior to tightening.

Corrugated roof sheets are predominantly single skin although insulated corrugated roof sheets can be supplied. They do carry a high price premium though.

What are the most popular kind of roof sheets and most common sizes available?

Trapezoidal, box section or metal roof cladding are all used to identify the most popular roof sheets. This is because they are available in a number of finishes and a wide range of colour.

They are often identified by their dimensions. For example 34/1000 or 32/1000. This means that the sheets have a crown height of 32mm and a cover width of 1000mm.

Our metal roofing sheets are cut to length which means that you are only paying for what you need, you avoid cutting the sheets and you end up with a professionally finished edge.

Frequently Asked Questions

How do I calculate roofing sheets?

Like every building, every roof can be different so it is important to calculate how many roofing sheets you will need to be able to provide your roof with full coverage and protection from severe weather conditions. To know this, you will need to calculate the approximate surface area of the roof. Whilst roofs can be flat and pitched, the most common roof style is the Pitch Roof, which uses a quantitative numerical measure of how steep a roof is. The roof’s pitch is its horizontal span (known as the run) divided by the vertical rise, calculating the slope of the roof. The pitch will inform your choice of your roofing materials. If you are using longer span aluminium roofing sheets, these sheets can be cut precisely to the exact length of the roof. Otherwise, feel free to ask for the size of roofing sheets made from other roofing materials. To quickly calculate the surface area of the roof, you should measure the length of the side of building as well as the width. Then, multiply these values together to get the approximate surface area of the roof.

How far apart do you put screws in metal roofing?

When installing a metal roof on your building, metal roofing screws will be the most important part of the job as they will hold everything together, ensuring that your roof is fully covered. Whilst installing your metal roof, it is important to make sure that you are not placing the roofing screws too close to each other or too far apart. In general, it is best to place each roofing screw around 1.5 to 2 feet apart, but we would not recommend placing them further apart than that as your roof could lose its integrity. Whilst screwing in the metal roof screws, it is important to use a proper screw gun such as one that is powered by an air compressor as this will ensure safety, as well as a strong finished look. To prevent rust or erosion, we would recommend using roofing screws with either washers or manufactured rubber caps so that your roof is effectively sealed.

Do anti condensation roof sheets work?

Anti-condensation roofing sheets are a cost-effective roofing solution that is designed to be installed on roofs which frequently suffer from the formation of condensation from the inside. When the temperature drops and the temperature of the roof sheet is lower than the dew point of the air that is below the roof sheet, condensation will occur on the underside of the metal roof sheets. This is caused by humidity affecting the cold metal of the roof sheet. Anti-condensation roof sheets aim to prevent dripping onto the floor, which can cause mould over time. They can be used on both domestic and commercial projects on a variety of buildings, including house extensions, garages, parapet roofs, agricultural buildings, uninsulated warehouses, and open shelters.

Anti-condensation roof sheets are defined as steel roof sheets which have been pre-coated with a fibre-based moisture-absorbing fabric on the underside. This fibre fabric gives these roofing sheets their anti-condensation properties with the potential to collect the condensation droplets, absorbing between 800g and 1kg of water per square metre. For most applications, this will be considered sufficient to prevent condensation. Between periods of condensation, the fabric dries out. In summary, the anti-condensation backing works by absorbing any formed droplets and retaining them until there is a rise in temperature which allows the moisture to naturally dissipate.

How much should corrugated sheets overlap?

After cutting the corrugated sheets to the desired length and pre-drilling any holes on the ridges (if appropriate), you should always overlap the sheets by at least one corrugation. When overlapping sheets, we would recommend using mastic lapping tape. Some corrugated sheets have pre-drilled holes. If your sheets do not, then you will need to drill holes in them using a 3⁄16 in (4.8 mm) drill bit. We would recommend keeping the spacing for the holes on the ends and sides of the panels around 6 to 8 inches (15 to 20 cm). When installing the corrugated sheets, we recommend placing them directly onto purlins that are attached to the roof trusses, starting on the outside edge. By closing or sealing off the ends with a plastic or wood strip underneath the panel at each end, this will stop rain leaking, noise from wind rattling the roof, and any unwanted pests sneaking in. To screw down the sheets, pre-drill the holes using 10 by 2 in (25.4 by 5.1 cm) screws with polycarbonate washers. Continue until the roof is completely covered, lapping over the previous panel by at least 2.5 inches. Adjust the lap so that the last sheet completes the coverage without making a lengthwise cut. If your roof has two sides and is not limited to a single slope, repeat the installation on the other side of the roof, installing a corrugated ridge cap as you proceed across with the sheets.

What is the standard size of a roofing sheet?

Standard lengths for roofing sheets are 8, 10 and 12 feet. Depending on the style of roofing you are looking for, the width of roofing sheets can vary greatly. To indicate how wide the roofing sheet needs to be to provide full coverage, the width of roofing sheets is simply measured straight across the top of the roofing sheet, from edge to edge. The two most common widths for roofing sheets are 26 and 36 inches. As well as these sizes, other standard widths include 24 and 39 inches. When calculating the coverage of roofing sheets using width and length, it is important to remember that each piece will need to overlap by several inches to ensure your roofing is fully effective. The other important measurement to remember for roofing sheets is thickness. The thickness of roofing sheets is expressed in gauges, with a high value indicating a thin roofing sheet and a lower value indicating a thicker roofing sheet. Standard roofing sheet gauges include 18, 20, 22, 24 and 26 gauge.

If you’d like to call and speak to us directly, please use 01792 893985.

The roofing sheets were perfectly cut to the size ordered and the supplied fittings were sufficient for the re-roofing job. One sheet was found to have minor distortion along one edge, possibly caused during its transport, but I did not spot this until after the driver had departed. It required gentle bending back into shape and is hardly noticeable now that it is fitted.

Overall, very good quality product and straightforward dealing with the company.

find us

Rollaclad Limited,

Rear Workshop,

995 Gorseinon Road,

Gorseinon,

Swansea,

SA4 9RU,

UK

products

info

About Us

Contact Us

Privacy Policy

Opening Hours:

Mon - Thurs: 08:30 to 17:00

Friday: 08:30 to 16:00

Saturday - Sunday: Closed